OPERATING INSTRUCTIONS

IMPORTANT

It is imperative that personnel responsible for the operation, and all operators of the Belchfire® equipment, read and understand these instructions prior to lighting and use of Belchfire® torches and equipment. All installation and operating shop procedures involving this equipment must comply with OSHA standards for Metal Fabricators, Section 1910 and American National Standards Institute ANSI Z229.1.

INTRODUCTION

The Belchfire® Gas-Air series torches are designed to operate with natural gas or propane, propylene, or MAPP gas, plus air supplied by shop air compressor systems.

WARNING: DO NOT USE ACETYLENE OR OXYGEN WITH THESE OR ANY OTHER BELCHFIRE® TORCHES HOOK-UP.

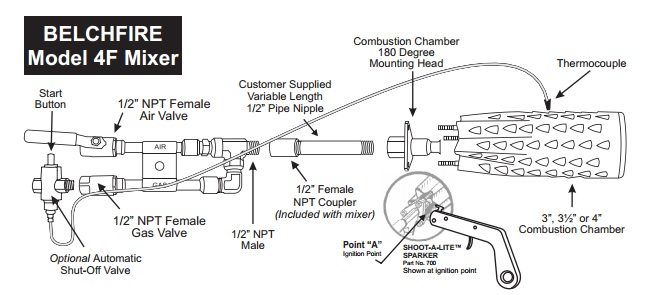

Maximum efficiency will be obtained if air and gas lines are at least 1/2” I.D. for the Model 4F torch. Air and fuel gas lines should be connected to torch fitting as shown on mounting bracket (Figure 1). Gas fittings are 1/2” NPT for Model 4F. Gas line pressure can be 1-25 PSI, as long as the withdrawal rates of the fuel used are not exceeded. Gas connections should be made only to a regulator designed to operate with the fuel gas to be used. Air pressure should be 80-120 PSI.

STARTING PROCEDURE FOR MODEL 4F WITH COMBUSTION CHAMBER

As with all fuel-burning torches, there is a certain amount of hazard involved with the operator and his use of the torch.

All normal safety precautions associated with this type of equipment should be observed. In addition, the following starting procedures should be followed:

1. Use supplied striker and position at rear opening of Combustion Chamber (Point “A”, Figure 1).

2. With striker positioned at Point A, open gas valve slowly until gas flows. Pull trigger on striker. Keep pulling trigger until gas ignites. If no gas ignites immediately, shut off gas by turning clockwise. Check for proper hook-up. If everything checks out, repeat starting procedure steps 1 and 2.

3. Once fuel is ignited, slowly open air valve 1/3 turn counter-clockwise. This will give you a starting flame.

FLAME ADJUSTMENT

The long, bright flame that appears when the torch is lit is fuel gas only, and to be useful, air must be added. This addition of air will cause the flame to start to turn blue and to shorten. As more air is added, the flame will become completely blue. This is a neutral flame and is the indication that the torch is burning all available fuel and operating at maximum efficiency. The addition of more air will cause orange feathers to appear, indicating excess air.

® Belchfire torches have a completely flexible flame which can be adjusted to suit any purpose. The size and type (lazy, long, neutral, oxidizing, etc.) of the flame is controlled by adjusting the valves (air and fuel) clockwise to decrease flame size and shut off, and counter-clockwise to increase flame size. When operating properly, the combustion chamber will be cherry red forward of the ignition point.

SHUT DOWN PROCEDURE

To insure long, trouble-free service from the torch, the following shut down procedure should be followed to allow the combustion chamber to cool down and prevent heat transfer to other portions of the torch.

1. Turn gas valve clockwise to stop.

2. Turn air valve clockwise until valve is 1/3 open. Allow air to flow for 15-20 seconds. Turn valve clockwise to stop.

3. Shut off fuel gas and air supply at the source and disconnect the torch.

SERVICE AND REPAIRS

® Belchfire torches will eventually require servicing or replacement of parts due to wear from normal use. All maintenance should be performed by authorized ® Belchfire service personnel. All repairs made by this personnel are fully guaranteed against defective material and workmanship. Repairs made or attempted by anyone other than this personnel cannot be guaranteed. ® Should any questions arise about the Belchfire torch, feel free to write or call us at any time. In any communications, please give model number of the torch.